Tanking in building construction refers to the process of applying a waterproof barrier to structures, particularly those below ground level, to prevent the ingress of water. This barrier acts as a protective envelope, shielding the structure from moisture and groundwater penetration. It’s most commonly applied to basements, cellars, retaining walls, lift pits, and other subterranean areas where water seepage poses a risk.

In essence, tanking ensures that a structure remains dry by either excluding water entirely or controlling its flow to prevent damage. It is a crucial aspect of waterproofing and forms part of a broader strategy to protect buildings from damp, rot, mold, and structural degradation. Without proper tanking, water can seep into foundations and underground rooms, causing costly long-term issues.

Importance of Tanking in Building Performance

Water may seem harmless, but it can be one of the most destructive forces acting on a building. Over time, moisture infiltration can compromise the integrity of concrete, corrode steel reinforcements, and lead to mold growth, impacting both the structural durability and the health of occupants.

Prevents Damp and Water Ingress

Tanking prevents water from entering a structure from the outside. This is especially important for underground spaces where hydrostatic pressure pushes moisture through cracks and porous materials. Without proper waterproofing, basements can become persistently damp or flooded.

Enhances Indoor Air Quality

Moist environments promote the growth of mold, mildew, and bacteria, which can severely affect indoor air quality and cause respiratory issues. Tanking minimizes this risk by keeping internal surfaces dry and unwelcoming to biological growth.

Maintains Structural Integrity

Water infiltration can weaken building materials over time. For instance, damp concrete can lead to the corrosion of embedded steel, reducing load-bearing capacity. Tanking safeguards against these forms of hidden degradation.

Adds Usable Space

By creating dry and stable below-ground areas, tanking increases the usable footprint of a property. It allows for safe storage, extra living space, or even commercial usage of basements that would otherwise be considered unusable.

Types of Tanking Systems and Materials

The choice of tanking system depends on several factors, including the structure’s location, depth, exposure to groundwater, and intended use of the space. Here’s an overview of the most common types:

Rigid (Cementitious) Tanking

This system involves applying a cement-based waterproof coating to internal or external walls and floors. It creates a rigid, impermeable barrier that resists water ingress.

- Best for: Concrete or masonry substrates

- Application: Brushed or trowelled on in layers

- Advantages: Easy to apply, good adhesion to mineral surfaces, cost-effective

- Limitations: Limited flexibility; prone to cracking if the building settles or shifts

Rigid tanking is ideal for areas with low to moderate water pressure and where structural movement is minimal. It is often used in new builds or where the surface preparation can be tightly controlled.

Flexible (Membrane) Tanking

This system uses flexible membranes to create a continuous waterproof barrier. These can be:

- Bituminous membranes: Made from asphalt-based products

- PVC or HDPE membranes: Synthetic plastic-based sheeting

- Composite membranes: Combining multiple layers for improved performance

- Best for: Areas with high water pressure or movement

- Application: Heat-welded, bonded, or laid loose with protective layers

- Advantages: High flexibility, durable, resists cracks and shifts

- Limitations: Requires skilled installation and careful detailing at joints

Flexible membranes are commonly used in high-risk environments where structural movement or hydrostatic pressure is expected.

Slurry-Applied Coatings and Crystalline Admixtures

Slurry coatings: Applied like paint, these contain waterproofing additives that block capillary paths in concrete.

Crystalline tanking systems: These penetrate the concrete and react with moisture to form crystals, effectively blocking water pathways.

- Best for: New builds or existing structures with exposed concrete

- Application: Brush, roller, or spray

- Advantages: Integrates with the substrate, self-sealing of minor cracks

- Limitations: Requires thorough surface prep and moisture for activation

These systems are becoming increasingly popular due to their ability to work from inside the structure and their long-term effectiveness.

Where and Why Tanking Is Used

Tanking plays a vital role in both residential and commercial construction, particularly in structures where water ingress poses a serious threat. It is most commonly used in:

- Basements and Cellars: These below-ground spaces are highly susceptible to water penetration due to hydrostatic pressure. Without proper tanking, moisture can seep through walls and floors, leading to mold, structural damage, and unusable space.

- Underground Rooms and Car Parks: Any part of a structure situated below ground level requires protection against water ingress. Tanking ensures durability, minimizes maintenance, and protects electrical systems or stored items.

- Retaining Walls: These walls hold back earth and often face groundwater or surface water exposure. Tanking protects the structural integrity of the wall, preventing leaks or erosion that could compromise stability.

- Podium Decks and Balconies: Although not underground, podium decks sit above habitable areas and require tanking to prevent water ingress from above. The tanking system prevents leaks that could damage ceilings, insulation, or finishes below.

- Tunnels and Subterranean Infrastructure: Infrastructure such as railway tunnels, pedestrian walkways, and utility conduits demand tanking systems to prevent water intrusion that could disrupt services or compromise safety.

- Bathrooms, Wet Rooms, and Kitchens: Internal spaces that experience high moisture and water usage also benefit from tanking. Especially in multi-storey buildings, tanking ensures that water does not seep through floors or walls, protecting other units or floors below.

In essence, tanking is used wherever water pressure can compromise the structure’s integrity or habitability. Proactive use of tanking increases a building’s resilience, prolongs material lifespan, and improves safety and comfort for occupants.

Tanking Application Process and Techniques

Installing an effective tanking system requires more than just applying a waterproofing product. It involves a series of critical steps and attention to detail:

- Substrate Preparation: This is the first and most important step. The surface must be clean, structurally sound, and free of contaminants like dust, oil, or loose particles. Uneven surfaces must be leveled, and cracks repaired to ensure full adhesion and effectiveness.

- Detailing for Corners and Junctions: Areas where walls meet floors or where different building elements intersect are common weak points. Tanking at these points often includes using reinforcing tapes, corner fillets, or pre-formed sealing strips to maintain a continuous barrier.

- Service Penetrations: Pipes, cables, and ducts that pass through tanked areas must be treated with care. Proper sealing with collars, gaskets, or flexible sealing compounds ensures that these penetrations don’t become leak paths.

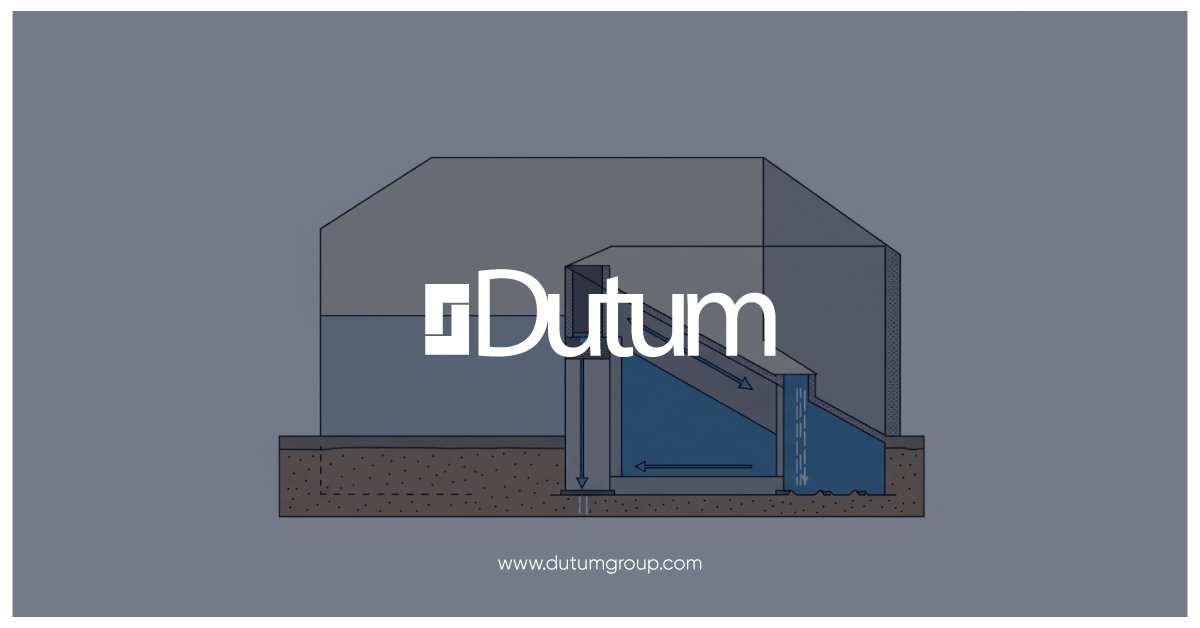

- Drainage Considerations: Before applying tanking, it’s vital to ensure that water has a designated path for exit, especially in basements and podium decks. Drainage membranes, sump pumps, and perimeter drains may be required in conjunction with tanking to manage hydrostatic pressure effectively.

- Application of the Tanking Material: Whether using a cementitious slurry, bituminous membrane, or crystalline coating, application methods vary. Cementitious products are usually brush- or trowel-applied, while membranes are rolled out and bonded to the substrate. Multiple coats may be necessary to achieve the required thickness and coverage.

- Curing and Drying: Curing time depends on the product used. During this period, the tanked area must be protected from physical damage, extreme temperatures, and water exposure. Premature backfilling or loading can compromise the system.

- Inspection and Testing: Once installed, the tanking system should be thoroughly inspected for continuity, bonding, and integrity. In some cases, water testing or flood testing is done to confirm waterproof performance before covering up.

Correct application ensures the longevity of the tanking system and avoids costly repairs down the line.

Dutum’s Expertise in Tanking and Basement Waterproofing

At Dutum Construction Group, we understand that effective tanking is about designing a system that works in harmony with the building’s structure, usage, and environmental context.

Our tanking approach involves:

- Conducting detailed site assessments to identify groundwater risks, soil types, and building needs

- Selecting appropriate waterproofing methods based on structural demands and budget

- Applying industry best practices during installation, including precise detailing at corners, joints, and service entries

- Performing rigorous quality checks, including flood tests, to ensure durability

With decades of experience in residential, commercial, and infrastructure projects across Nigeria, we deliver reliable waterproofing solutions that stand the test of time.

Contact Us

Visit our website at Dutum Group

Email: info@dutumgroup.com

We are proudly located in:

Abuja:

10 Danube Close, Off Danube Crescent, Maitama

Phone: +234 805 831 7200

Lagos:

2 Abisogun Road, Off Palace Road, Oniru Estate, Maroko

Phone: +234 805 831 7200

Ibadan:

Isaac’s Place, Opp. TOTAL Petrol Station, Onireke, G.R.A Dugbe

Phone: +234 706 967 1901

Conclusion

Tanking is a foundational step toward building longevity, safety, and comfort. By keeping water out, it protects structural elements, reduces maintenance burdens, and fosters healthy living environments.

With the right expertise, materials, and commitment to quality, tanking becomes an investment in your building’s future, and with Dutum, you can be confident that your foundation is sealed, secure, and built to last.

Leave a Reply